Some Of Our Works

Personnel

Steve Ramm - CEO and Engineer

– BEng in Mechanical Engineering (Stevens Institute of Technology)

– MSc in Computational Fluid Dynamics (Cranfield University)

– Over 20 years of experience in race car aerodynamics and mechanical engineering.

– Over 30 years of CAD/CAM experience

– Over 15 years of composites engineering and manufacturing experience.

Services

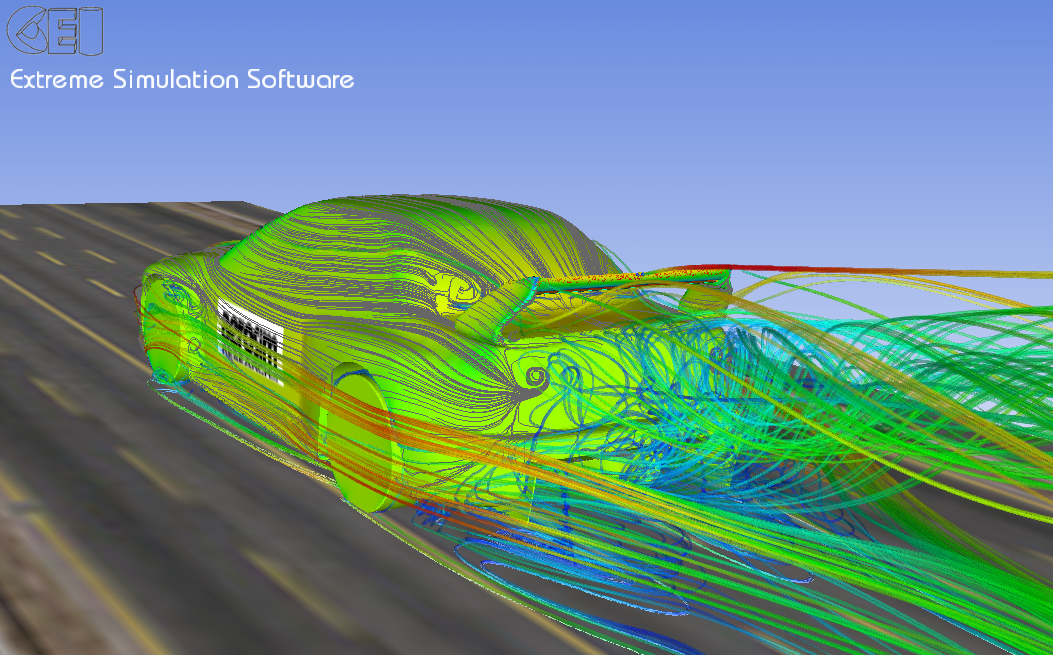

CFD/Aero Engineering

We specialize in subsonic aerodynamics and CFD simulations. Our capabilities include design and simulation of the following:

-Single and multi-element airfoils.

-Ducting and heat exchanger packages.

-Ground effects.

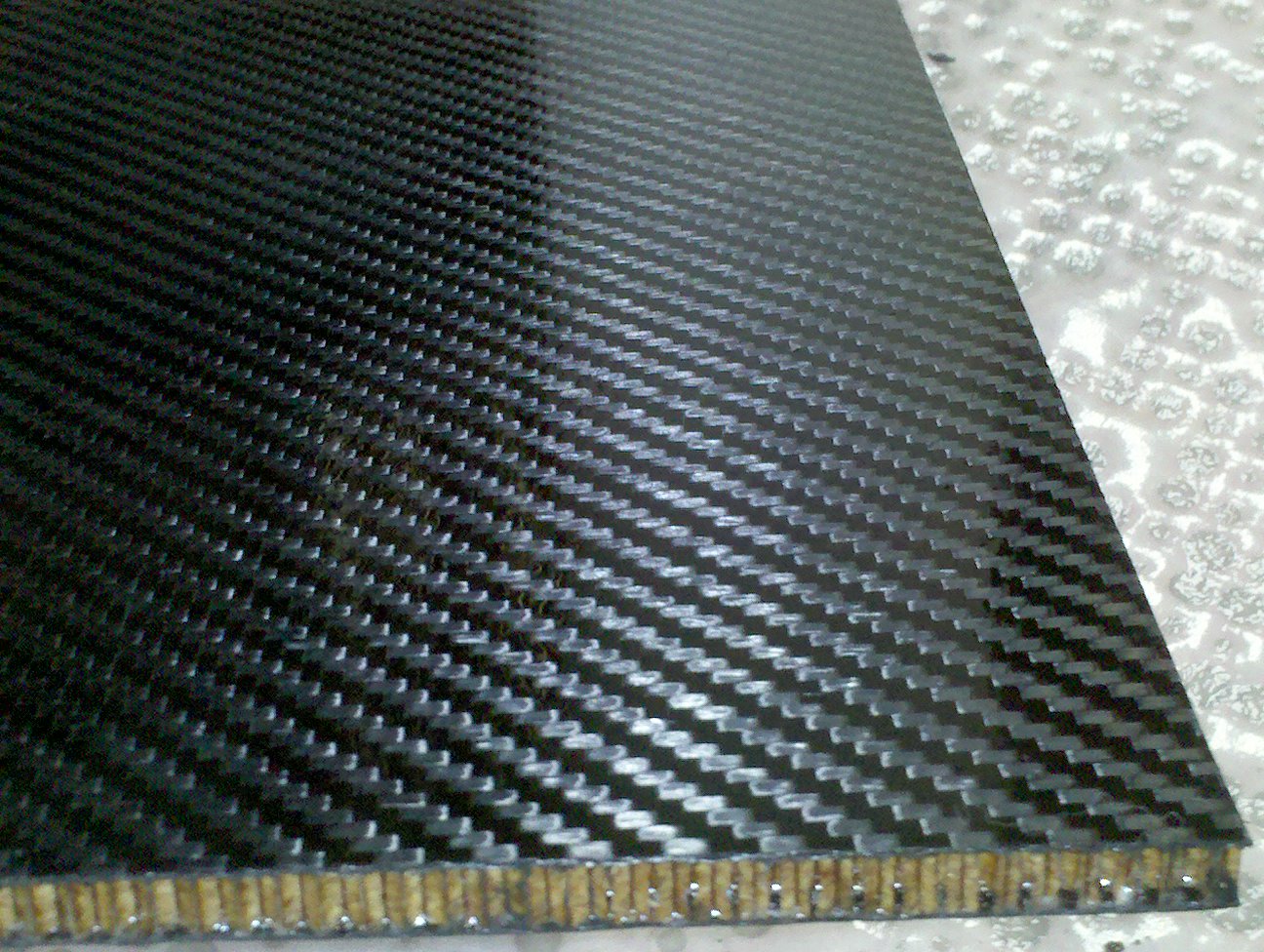

Composites

In addition to designing and manufacturing our line of Subaru composite parts, we also design and manufacture components for both automotive and aerospace industries. Depending on the budget and required performance, we can manufacture components via different methods, from vacuum infusion (VARTM) to autoclaved prepreg. We also have the capability of machining tooling in house from high density foam, Renshape or aluminum.

CNC Machining

We have a small machine shop in-house, consisting of a Mori-Seiki MV40B 3 axis CNC mill, a Bridgeport Series 2 mill, lathe, bandsaw, drill press and a Miller Synchrowave 250DX TIG welder. We are able to design and manufacture short production runs and prototypes in aluminum, steel and other machinable alloys up to 30″ x 16″ x 20″.

CAD Design/Engineering

We have extensive experience in solid modeling and currently utilize SolidEdge 3D CAD software. We can go from concept to 3D solid model to prototype or short run production in house. We can also perform FEA analysis for both isotropic and anisotropic materials in addition to our CFD capabilities.

Latest News

-

A new, high temperature mold will be finished this week which will allow us to make the sunroof panels in oven cured prepreg carbon fiber. ... Read More

-

Group Buy Pre-Orders for Subaru GV and VA Carbon Roof Panels

We’ve started a group buy for the Subaru GV and VA Carbon Roof Panels. More information can be found in the shop section under the... Read More -

Finally, starting to take orders for new parts …

I’ve changed the construction of all of the composite parts to oven cured prepreg carbon fiber. The oven is done and I’m back to work... Read More -